As the quality of life continuously improves, consumers have increased expectations for the quality of clothing, food, housing and transportation. This is particularly obvious for food, beverage, medical and automobile products because qualities of these products can heavily influence human life and health. Therefore it has drawn enormous attention from enterprises and manufacturers to focus on these products' quality assurance. Notably, the quality control of relevant materials used in the production of these products plays an important factor in determining the overall product quality. Labthink's professional testing laboratory provides outsourced testing services for food and beverage producers, medical, pharmaceutical and cosmetics companies, and packaging and automobile manufacturers and many other industries and help them better determine and control their product qualities.

1. Testing Scope:

1.1 Barrier Property Tests of Films and Paper:

1.1.1 Oxygen permeability test of various films and paper

1.1.2 Nitrogen permeability test of various films and paper

1.1.3 Carbon dioxide permeability test of various films and paper

1.1.4 Water vapor permeability test of various films and paper

1.2 Mechanical Strength Tests of Films and Paper

Test items including but not limited to: tensile strength, heat seal strength, peel strength, tearing strength, and thickness, etc.

Common testable materials: PE, LDPE, HDPE, PP, BOPP, CPP, PET, PA, EVOH, EVAL, PVC, PVDC, AL, KOP, KPET, KPA, KMF, aluminum-plated PET, aluminum coated CPP, BOPP with matte surface treatment, PA/AL/CPP, PA/PU, PET/AL/PA, PE/AL/PET, five-layer co-extrusion film, seven-layer co-extrusion film

1.3 Barrier Property Tests of Bottles and Bags:

Commonly testable products including but not limited to: beer bottle, coke bottle and mineral water bottle, etc.

1.4 Automotive Interior Decoration Tests:

1.4.1 Fogging test

Commonly testable material including but not limited to: foamed materials, textile, non-woven fabrics, leatheroid, leather, instrument board, headlight, and cushion material, cotton cloth, etc.;

Others: fogging properties of raw materials in the state of liquid, paste, powder and solid, etc.

1.4.2 Air permeability test

Commonly testable material including but not limited to: Leather, leatheroid, non-woven fabrics, thermal insulating film, and battery diaphragm, etc.

1.4.3 Water vapor permeability test

Leather, leatheroid, non-woven fabrics, fabrics, etc.

1.5 Adhesive Strength Test

Various adhesive products

1.6 Barrier Property Tests of Construction Materials and Solar Back-sheets

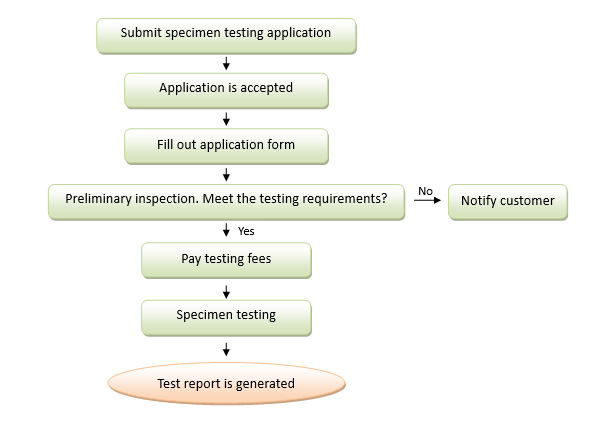

2. Service Workflow

3. Test Items

3.1 Standard Test Items

| NO. | Test Item | Condition | Material | Standards to Follow (If Any) |

| 1 | Air Transmission Rate

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 2 | Air Transmission Rate

(Equal Pressure Method) | 23°C, 0%RH | Film/Sheeting | ASTM D3985-2005(2010)e1

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 3 | Oxygen Transmission Rate

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 4 | Oxygen Transmission Rate

(Equal Pressure Method) | 23°C, 0%RH | Film/Sheeting | ASTM D3985-2005(2010)e1

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 5 | Carbon Dioxide Transmission Rate

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 6 | Nitrogen Transmission Rate | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 7 | Oxygen Transmission Rate (Container) | 23°C, 0%RH | Container | ASTM F1307-2002(2007)

ASTM D3985-2005(2010)e1

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 8 | Air Transmission Rate (Container) | 23°C, Ambient | Container | ASTM F1307-2002(2007)

ASTM D3985-2005(2010)e1

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 9 | Water Vapor Transmission Rate

(Gravimetric/Dish Method) | 38°C, 90%RH | Film/Sheeting | ISO 2528-1995

ASTM E96/E96M-2012

TAPPI T448 OM-09 |

| 10 | Water Vapor Transmission Rate

(Electrolytic Detection Sensor Method) | 38°C, 90%RH | Film/Sheeting | ISO 15106.3-2003 |

| 11 | Water Vapor Transmission Rate

(Infrared Detection Sensor Method) | 38°C, 90%RH | Film/Sheeting | ASTM F1249-13

ISO 15106.2-2003

TAPPI T557 wd-04 |

| 12 | Water Vapor Transmission Rate

(Humidity Detection Sensor Method) | 38°C, 90%RH | Film/Sheeting | ASTM E398-13

ISO 15106.1-2003 |

| 13 | Water Vapor Transmission Rate of Container

(Electrolytic Detection Sensor Method) | 38°C, 90%RH | Container | ISO 15106.3-2003 |

| 14 | Water Vapor Transmission Rate of Container

(Infrared Detection Sensor Method) | 38°C, 90%RH | Container | ASTM F1249-13

ISO 15106.2-2003 |

| 15 | Oxygen Transmission Rate after Flex

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 16 | Oxygen Transmission Rate after Flex

(Equal Pressure Method) | 23°C, 0%RH | Film/Sheeting | ASTM D3985-2005(2010)e1

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 17 | Nitrogen Transmission Rate after Flex

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 18 | Carbon Dioxide Transmission Rate after Flex

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 19 | Air Transmission Rate after Flex

(Differential Pressure Method) | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 20 | Water Vapor Transmission Rate after Flex

(Gravimetric/Dish Method) | 38°C, 90%RH | Film/Sheeting | ISO 2528-1995

ASTM E96/E96M-2012 |

| 21 | Tensile Strength and Elongation Rate

(Lateral) | 23°C, 50%RH | Film/Sheeting | ISO 527-1:2012

ISO 527-3:1995

ASTM D882-2012 |

| 22 | Tensile Strength and Elongation Rate

(Longitudinal) | 23°C, 50%RH | Film/Sheeting | ISO 527-1:2012

ISO 527-3:1995

ASTM D882-2012 |

| 23 | Coefficient of Friction | 23°C, 50%RH | Film/Sheeting | ISO 8295-1995

ASTM D1894-2011e1 |

| 24 | Mechanical Contacting Thickness Test | 23°C, 50%RH | Film/Sheeting | ISO 4593:1993

ASTM D374M-13

TAPPI T411 om-10

ISO 3034-2011

ISO 534-2011 |

| 25 | Heat Seal Strength | 23°C, 50%RH | Film/Sheeting | ASTM F88/F88M-2009 |

| 26 | Shrinking Force and Shrinkage Ratio

(Lateral) | 23°C, 50%RH | Film/Sheeting | ISO 14616-1997

DIN 53369-1976 |

| 27 | Shrinking Force and Shrinkage Ratio

(Longitudinal) | 23°C, 50%RH | Film/Sheeting | ISO 14616-1997

DIN 53369-1976 |

| 28 | Falling Dart Impact Energy | 23°C, 50%RH | Film/Sheeting | ISO 7765.1-1988

ASTM D1709-2009 |

| 29 | Pendulum Impact Energy | 23°C, 50%RH | Film/Sheeting | ASTM D3420-2008a |

| 30 | Tear Strength

(Elmendorf Method, Lateral) | 23°C, 50%RH | Film/Sheeting | ISO 6383.2-1983

ASTM D1922-2009

ISO1974-2012

TAPPI T414 om-12 |

| 31 | Tear Strength

(Elmendorf Method, Longitudinal) | 23°C, 50%RH | Film/Sheeting | ISO 6383.2-1983

ASTM D1922-2009

ISO1974-2012

TAPPI T414 om-12 |

| 32 | Tear Strength

(Trouser Tear Method, Lateral) | 23°C, 50%RH | Film/Sheeting | ISO 6383.1-1983

ASTM D1938-2008 |

| 33 | Tear Strength

(Trouser Tear Method, Longitudinal) | 23°C, 50%RH | Film/Sheeting | ISO 6383.1-1983

ASTM D1938-2008 |

| 34 | Tear Strength

(Right Angled Tear Method, Lateral) | 23°C, 50%RH | Film/Sheeting | ASTM D1004-2013 |

| 35 | Tear Strength

(Right Angled Tear Method, Longitudinal) | 23°C, 50%RH | Film/Sheeting | ASTM D1004-2013 |

| 36 | Peel Strength (Lateral) | 23°C, 50%RH | Film/Sheeting | ASTM F904-1998(2008) |

| 37 | Peel Strength (Longitudinal) | 23°C, 50%RH | Film/Sheeting | ASTM F904-1998(2008) |

| 38 | Hot Tack Strength | As Required | Film/Sheeting | ASTM F2029-2008 |

| 39 | Puncture Resistance | 23°C, 50%RH | Film/Sheeting | NA |

| 40 | Burst | 23°C, 50%RH | Film/Sheeting | ASTM F1140/F1140M-2013 |

| 41 | Creep | 23°C, 50%RH | Film/Sheeting | ASTM F1140/F1140M-2013 |

| 42 | Creep To Burst | 23°C, 50%RH | Film/Sheeting | ASTM F1140/F1140M-2013 |

| 43 | Seal Strength of Open Package | 23°C, 50%RH | Film/Sheeting | ASTM F1140/F1140M-2013 |

| 44 | Seal Strength with Expansion Restriction | 23°C, 50%RH | Film/Sheeting | ASTM F2054/F2054M-13 |

| 45 | Residual Oxygen Analysis of Vacuum Package | 23°C, 50%RH | Container | NA |

| 46 | Residual Oxygen Analysis of Vacuum Package | 23°C, 50%RH | Film/Sheeting | NA |

| 47 | Helium Transmission Rate | 23°C, 0%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 48 | Oxygen Transmission Rate-Equal Pressure Method (Container) | 23°C, 100%RH | Container | ASTM F1307-2002(2007)

ASTM D3985-2005(2010)el

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 49 | Oxygen Transmission Rate-Equal Pressure Method (Container) | 15-55°C, 35%-90%RH | Container | ASTM F1307-2002(2007)

ASTM D3985-2005(2010)el

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 50 | Carbon Dioxide Transmission Rate-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 51 | Carbon Dioxide Transmission Rate-Differential Pressure Method | 5-95°C, 10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 52 | Nitrogen Transmission Rate-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 53 | Nitrogen Transmission Rate-Differential Pressure Method | 5-95°C,

10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 54 | Oxygen Transmission Rate-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 55 | Oxygen Transmission Rate-Differential Pressure Method | 5-95°C,

10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 56 | Air Transmission Rate-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 57 | Air Transmission Rate-Differential Pressure Method | 5-95°C,

10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 58 | Oxygen Transmission Rate-Equal Pressure Method | 23°C, 100%RH | Film/Sheeting | ASTM F1927-2007

ISO 15105-2:2003

ASTM D3985-2005(2010)e1 |

| 59 | Oxygen Transmission Rate-Equal Pressure Method | 10-55°C,

35%-90%RH | Film/Sheeting | ASTM F1927-2007

ISO 15105-2:2003

ASTM D3985-2005(2010)e1 |

| 60 | Water Vapor Transmission Rate-Gravimetric/Dish Method | 15-55°C,

35%-90%RH | Film/Sheeting | ISO 2528-1995

ASTM E96/E96M-2012

TAPPI T464 om-12 |

| 61 | Water Vapor Transmission Rate-Electrolytic Detection Sensor Method | 38°C, 100%RH | Film/Sheeting | ISO 15106.3-2003 |

| 62 | Water Vapor Transmission Rate-Electrolytic Detection Sensor Method | 15-55°C,

35%-90%RH | Film/Sheeting | ISO 15106.3-2003 |

| 63 | Water Vapor Transmission Rate-Infrared Detection Sensor Method | 15-55°C,

35%-90%RH | Film/Sheeting | ASTM F1249-13

ISO 15106.2-2003

TAPPI T557 wd-04 |

| 64 | Water Vapor Transmission Rate-Infrared Detection Sensor Method | 38°C, 100%RH | Film/Sheeting | ASTM F1249-13

ISO 15106.2-2003

TAPPI T557 wd-04 |

| 65 | Water Vapor Transmission Rate-Humidity Detection Sensor Method | 15-55°C,

35%-90%RH | Film/Sheeting | ASTM E398-13

ISO 15106.1-2003 |

| 66 | Water Vapor Transmission Rate-Electrolytic Detection Sensor Method (Container) | 38°C, 100%RH | Container | ISO 15106.3-2003 |

| 67 | Water Vapor Transmission Rate-Electrolytic Detection Sensor Method (Container) | 15-55°C, 35%-90%RH | Container | ISO 15106.3-2003 |

| 68 | Oxygen Transmission Rate after Flex-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 69 | Oxygen Transmission Rate after Flex-Differential Pressure Method | 5-95°C,

10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 70 | Oxygen Transmission Rate after Flex- Equal Pressure Method | 23°C, 100%RH | Film/Sheeting | ASTM F1927-2007

ISO 15105-2:2003

ASTM D3985-2005(2010)e1 |

| 71 | Oxygen Transmission Rate after Flex-Equal Pressure Method | 10-55°C,

35%-90%RH | Film/Sheeting | ASTM F1927-2007

ISO 15105-2:2003

ASTM D3985-2005(2010)e1 |

| 72 | Nitrogen Transmission Rate after Flex-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 73 | Nitrogen Transmission Rate after Flex-Differential Pressure Method | 5-95°C,

10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

Reference:

ASTM D1434-1982(2009)e1 |

| 74 | Carbon Dioxide Transmission Rate after Flex-Differential Pressure Method | 23°C, 100%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 75 | Carbon Dioxide Transmission Rate after Flex-Differential Pressure Method | 5-95°C,

10%-90%RH | Film/Sheeting | ISO 2556-1974

ISO 15105-1:2007

ASTM D1434-1982(2009)e1 |

| 76 | Coefficient of Friction | Room temperature ~ 99.9°C | Film/Sheeting | ASTM D1894-2011e1 |

| 77 | Stress at Definite Elongation (Longitudinal) | Ambient | Film/Sheeting | ISO 527-1:2012

ISO 527-3:1995

ASTM D882-2012 |

| 78 | Stress at Definite Elongation (Lateral) | Ambient | Film/Sheeting | ISO 527-1:2012

ISO 527-3:1995

ASTM D882-2012 |

| 79 | Air Transmission Rate-Equal Pressure Method | 23°C, 100%RH | Container | ASTM F1307-2002(2007)

ASTM D3985-2005(2010)el

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 80 | Air Transmission Rate-Equal Pressure Method | 15-55°C,

35%-90%RH | Container | ASTM F1307-2002(2007)

ASTM D3985-2005(2010)el

ASTM F1927-2007

ISO 15105-2:2003

ASTM F2622-08(2013) |

| 81 | Rotary Torque of Bottle Cap | Ambient | Container | ASTM D2063/D2063M-2010(2012)

ASTM D3198-1997(2007)

ASTM D3474-1990(2012) |

| 82 | Seal Performance (Negative Pressure Method) | Ambient | Film/Sheeting | ASTM D3078-02(2013) |

| 83 | Seal Performance (Negative Pressure Method) | Ambient | Container | ASTM D3078-02(2013) |

| 84 | Flex Durability of Film (Turpentine Method) | Ambient | Film/Sheeting | ASTM F392/F392M-2011 |

| 85 | Primary Adhesion | Ambient | Film/Sheeting | NA |

| 86 | Lasting Adhesion | Ambient | Film/Sheeting | NA |

| 87 | Ink Layer Fastness | Ambient | Film/Sheeting | NA |

| 88 | Headspace Oxygen and Carbon Dioxide Analysis | Ambient | Film/Sheeting | NA |

| 89 | Residual Oxygen Analysis of Glass Bottle and Metal Jar | Ambient | Container | NA |

| 90 | Steaming and Boiling Resistance | Ambient | Film/Sheeting | NA |

| 91 | Seal Performance after Steaming and Boiling (Negative Pressure Method) | Ambient | Film/Sheeting | ASTM D3078-02(2013) |

| 92 | Cold Resistance | Ambient | Film/Sheeting | NA |

| 93 | Transmittance | Ambient | Film/Sheeting | ASTM D1003-2011e1 |

| 94 | Haze | Ambient | Film/Sheeting | ASTM D1003-2011e1 |

| 95 | Heat Shrinkage Ratio (Lateral) | Ambient | Film/Sheeting | ASTM D2732-2008 |

| 96 | Heat Shrinkage Ratio (Longitudinal) | Ambient | Film/Sheeting | ASTM D2732-2008 |

| 97 | Gas Transmission Rate of Packaging Films at Extreme High and Low Temperature (Data Fitting) | As Required | Film/Sheeting | NA |

| 98 | Seal Temperature, Pressure and Dwell Time * | Ambient | Film/Sheeting | ASTM F88/F88M-2009

ASTM F2029-2008 |

| 99 | 180 Degree Peel Strength (Lateral) | Ambient | Adhesives | NA |

| 100 | 180 Degree Peel Strength (Longitudinal) | Ambient | Adhesives | NA |

| 101 | 90 Degree Peel Strength (Lateral) | Ambient | Adhesives | NA |

| 102 | 90 Degree Peel Strength (Longitudinal) | Ambient | Adhesives | NA |

| 103 | Carbon Dioxide Transmission Rate of Containers | Ambient | Carbonated Beverage Bottle | NA |

| 104 | Water Vapor Transmission Rate of Construction Materials | NA | Construction Material | NA |

| 105 | Gas Transmission Rate of Special Materials * | NA | Special Material | NA |

| 106 | Organic Gas Permeability | NA | Film/Sheeting | NA |

| 107 | Flammable and Explosive Gas Transmission Rate | NA | Film/Sheeting | NA |

| 108 | Gas Transmission Rate of Battery Diaphragms | NA | Battery Diaphragm | NA |

| 109 | Oxygen Transmission Rate of Contact Lenses | NA | Contact Lense | NA |

| 110 | Removing Force of Caps | Ambient | Container | NA |

| 111 | Opening Force | Ambient | Container | NA |

| 112 | Pullout Force of Brush Hair | Ambient | NA | NA |

| 113 | Compressive Resistance of Paper Cartons | Ambient | Paper Carton | NA |

| 114 | Fogging Test (Garevimetric Method) | Ambient | NA | NA |

| 115 | Fogging Test (Gloss Method) | Ambient | NA | NA |

| 116 | Fogging Test (Haze Method) | Ambient | NA | NA |

| 117 | Gas Transmission Rate of Porous Materials | Ambient | NA | NA |

| 118 | Abrasion Resistance | Ambient | Presswork | NA |

| 119 | Suspension Force | Ambient | Infusion Bottle | NA |

| 120 | Seal Performance at Drug Injection Point | Ambient | Infusion Bottle | NA |

| 121 | Permeation Resistance at Puncture Area | Ambient | Infusion Bottle | NA |

| 122 | Seal Performance of Injector and Permeation Resistance at Injection Point | Ambient | Infusion Bottle | NA |

| 123 | Self Adhesion | Ambient | Self-adhesive Plastic Wrap | NA |

Remarks for the items marked with "*"

1. Determination of Heat Seal Parameters

1.1 $70 is charged for each test, which means performing a heat seal strength test at a specific temperature, pressure and dwell time.

1.2 At least 15 tests are required to obtain the optimized heat sealing parameters, which means customers will be provided with 15 heat seal strength results, each at different sealing temperature, pressure and dwell time. Besides, the optimized heat sealing parameters will be recommended.

2. Gas Transmission Rate of Specific Materials

Specific materials refer to very thick, rigid or uneven ones on which gas transmission rate test cannot be performed with regular instruments. Specific procedures will be applied to carry on such test.

3.2 CNAS Certified Test Items

| ID | Test Items | Code of Field | Title, Code of Standard or Method | Limitation | Note |

| 1 | Water Vapor Transmission Rate | 0315 | Sheet Materials-Determination of Water Vapour Ttransmission Rate- Gravimetric (dish) Method

ISO 2528-1995 | | |

| 2 | Water Vapor Transmission Rate | 0315 | Plastics-Film and Sheeting-Determination of Water Vapour Transmission Rate-Part 3:Electrolytic Detection Sensor Method

ISO 15106.3-2003 | | |

| 3 | Water Vapor Transmission Rate | 0315 | Standard Test Methods for Water Vapor Transmission of Materials

ASTM E96/E96M-2012 | | |

| 4 | Oxygen Transmission Rate | 0315 | Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor

ASTM D3985-2005(2010)e1 | | |

| 5 | Oxygen Transmission Rate | 0315 | Standard Test Method for Determination of Oxygen Gas Transmission Rate,Permeability and Permeance at Controlled Relative Humidity Through Barrier Materials Using a Coulometric Detector

ASTM F1927-2007 | | |

| 6 | Gas Transmission Rate | 0315 | Plastics-Film and Sheeting-Determination of Gas Transmission-Differential-pressure Method

GB/T 1038-2000 | Oxygen | Negotiation for Others |

| 7 | Gas Transmission Rate | 0315 | Nitrogen |

| 8 | Gas Transmission Rate | 0315 | Carbon Dioxide |

| 9 | Gas Transmission Rate | 0315 | Air |

| 10 | Gas Transmission Rate | 0315 | Plastics-Film and Sheeting-Determination of Gas Transmission Rate-Part1:Differential-pressure Methods

ISO 15105.1-2007 | Oxygen | |

| 11 | Gas Transmission Rate | 0315 | Nitrogen |

| 12 | Gas Transmission Rate | 0315 | Carbon Dioxide |

| 13 | Gas Transmission Rate | 0315 | Air |

| 14 | Thickness | 0315 | Plastics-Film and Sheeting-Determination of Thickness by Mechanical Scanning

ISO 4593-1993 | | |

| 15 | Thickness | 0315 | Standard Test Methods for Thickness of Solid Electrical Insulation

ASTM D374-1999 (2005) | | |

| 16 | Tensile Properties | 0315 | Plastics-Determination of Tensile Proterties-Part 1: General Principles

ISO 527.1-2012

Plastics - Determination of Tensile Properties - Part 3: Test Conditions for Films and Sheets

ISO 527.3-1995 | Only for Tensile Strength and Nominal Tensile Break Strain | |

| 17 | Tensile Properties | 0315 | Standard Test Method for Tensile Properties of Thin Plastic Sheeting

ASTM D882-2012 | Only for Tensile Strength and Nominal Tensile Break Strain | |

| 18 | Tear Resistance | 0315 | Plastics-Film and Sheeting-Determination of Tear Resistance-Trouser Tear Method (Elmendorf)

ISO 6383.2-1983 | | |

| 19 | Tear Resistance | 0315 | Standard Test Method for Tear Resistance (Graves Tear) of Plastic Film and Sheeting

ASTM D1004-2013 | | |

| 20 | Tear Resistance | 0315 | Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

ASTM D1922-2009 | | |

| 21 | Coefficient of Friction | 0315 | Plastics-Film and Sheeting-Determination of the Coefficients of Friction

ISO 8295-1995 | | |

| 22 | Coefficient of Friction | 0315 | Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

ASTM D1894-2011e1 | | |

| 23 | Peel Strength | 0315 | Standard Test Method for Comparison of Bond Strength or Ply Adhesion of Similar Laminates Made from Flexible Materials

ASTM F904-1998 (2008) | | |

| 24 | Heat Shrinkage Properties | 0315 | Plastics-Heatshrinkable Films of Polyethylene, Ethylene Copolymers and Their Mixtures-Determination of Shrinkage Stress and Contraction Stress

ISO 14616-1997 | | Two Directions |

| 25 | Heat Shrinkage Properties | 0315 | Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting ASTM D2732-2008 | |

| 26 | Heat Shrinkage Properties | 0315 | Testing of Plastic Films-Determination of the Shrinking Stress

DIN 53369-1976 | |

| 27 | Heat Seal Strength | 0315 | Standard Practices for Making Heatseals for Determination of Heatsealability of Flexible Webs as Measured by Seal Strength

ASTM F2029-2008 | | |

| 28 | Falling Dart Impact Properties | 0315 | Plastics-Film and Sheeting-Determination of Impact Resistance-Free Falling Dart Method-Part 1:Staircase Method

ISO 7765.1-1988 | | |

| 29 | Falling Dart Impact Properties | 0315 | Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

ASTM D1709-2009 | | |

| 30 | Flex Durability | 0315 | Standard Test Method for Flex Durability of Flexible Barrier Materials

ASTM F392/F392M-2011 | | Turpentine Method |

4. Specimen Requirements

4.1 Raw Material

4.1.1 Barrier tests: at least 6 specimens are required for each test; specimen should be flat and integral with at least 100 mm in width and at most 3 mm in thickness.

4.1.2 Flex durability tests: at least 5 specimens are required for each test; each specimen should be at least 280 mm in length and 200 mm in width; for film bags, dimension is calculated when it is unfolded.

4.1.3 Falling dart impact tests: at least 30 specimens are required; specimen should be flat and integral with at least 150 mm in both length and width.

4.1.4 Other mechanical tests: at least 20 specimens are required; specimen should be flat and integral with at least 250 mm in length and 200 mm in width; for heat seal test, specimen length should be at least 350 mm.

4.1.5 All raw materials should be

a. without scratch, abrasion, damage, pinhole, or creases; without contamination; with intact ink layer; never contacted with unknown matter or exposed to an environment that may compromise test results; kept dry and clean.

b. Coiled before sent out to avoid wrinkles (for films and composite films only).

c. Sealed in uncontaminated, protective, and intact bags (for film bags and sheets only).

d. Sealed in dry, uncontaminated, protective, and intact bags or containers (for plastic containers only).

4.2 Finished Package

4.2.1 For leak test, heat seal test, and residual oxygen test, at least 10 finished packages with content filled in, 10 heat-sealed finished packages without content, and 5 defective finished packages with content filled in are required; each specimen should be at most 250 mm in length and 180 mm in width.

4.2.2 For headspace gas analysis test, at least 10 finished packages with content filled in, 10 heat-sealed finished packages without content, and 5 defective finished packages with content filled in are required; each specimen should contain at least 15 mL gas.

4.2.3 All finished packages should be:

a. finished packages with content filled in and heat-sealed finished packages without content should be out of scratch, abrasion, damage, pinholes, and creases; without contamination; with intact ink layer; never contacted with unknown matter or exposed to an environment that may compromise test results; kept dry and clean.

b. finished packages with content filled in, heat-sealed finished packages without content, and defective finished packages with content filled in should be kept separately before sent out.

4.3 Other Things to Be Noted

4.3.1 Test standard should be stated when the test application form is submitted. If no available test standard could be applied, test method should be negotiated.

4.3.2 If quantity of the test specimens does not meet the above requirements, test results could be only calculated from tests of the provided specimens.

4.3.3 Customers need to provide information such as the full name, specification, material and batch number of the specimen and notify Labthink whether the specimen should be returned.

5. Test Duration

5.1 Barrier Property Tests: 14 days for 5 or less types of specimens to be tested (7 days for expedited service). Test duration shall be negotiated for over 5 types of specimens to be tested.

5.2 GTR Tests of Organic Gas, Hazardous Gas or Package: 28 days for 3 or less types of specimens to be tested (14 days for expedited service). Test duration shall be negotiated for over 3 types of specimens to be tested.

5.3 Other Test Items: 5 days (3 days for expedited service)

5.4 The charge of expedited testing service is twice of regular testing service.

5.5 Any disagreements of the report shall be stated within 10 days after the receipt of the report.

6. Disclaimer

In no event will Labthink be responsible for any damages or penalties resulting from Labthink’s testing services or reporting of results or from use or distribution of the materials tested. Although Labthink endeavors to provide accurate testing and reporting, the testing and reporting of results are provided by Labthink without any warranty, express or implied, as to their accuracy. In no event will Labthink be liable for any direct, indirect, special, punitive, or consequential damages resulting from the testing or reporting of test results. Customer agrees to indemnify and hold harmless Labthink against any claims arising out of customer’s use, sale, or distribution of materials tested and against any claims arising out of customer’s breach.

Labthink reserves the right of final explanation to all the above notes.